Our development

We have many years of industry experience, the main products are Rubber

Compound, rubber products molds and so on

1992

Established a factory mainly produce rubber hose in Hangzhou in 1992.

Invested a production line manufactures rubber compounds in 2010.

2010

2022

2023

2024

Moved all the production line to Anhui in 2022.

Invested to build a new plant of 30,000 m2 in Anhui and at the same year, set up a factory in Vietnam in 2023.

Set up a rubber compound production line in cooperation with one of major Russian customers to better serve local customers in 2024.

Our Advantages

Superior formulas optimized for your equipment.

Longer-lasting rubber compounds to stretch your investment.

Rapid, proactive service, and support.

-

EPDM Rubber Compound

EPDM Rubber Compound is a blank for the manufacture of rubber products, that is, semi-finished products, so the colloidal dispersion quality of the compound is directly related to the quality of the finished product, while the viscoelastic and rheological properties of the compound directly affect the processing properties such as calendering and extrusion.

-

Auto Rubber Ring

PANDA can use all kinds of rubber compounds to produce a variety of commercial and industrial molded parts, such as sealing parts, appearance parts, shock absorption parts, foot pads, etc.

-

EPDM rubber strips

advanced formulation technologyand modern microwave vulcanization line are used to produce EPDM rubber strip, which keeps the unique performanceof EPDM. The production of doors and windows, curtain wall sealing strip to meet the national standard quality, at roomtemperature for 15 years, All products can be designed and produced according to customers quality and specifications.

-

Air Hose

PANDA can use all kinds of rubber compounds to produce a variety of commercial and industrial rubber hose. Identified by material, mainly are EPDM rubber hose, NBR rubber hose, Nature rubber hose. Identified by application, mainly are garden hose, air hose, oxy-acetylene welding hose, fuel/diesel hose, cooling water hose, etc.

-

Garden Hose

PANDA can use all kinds of rubber compounds to produce a variety of commercial and industrial rubber hose. Identified by material, mainly are EPDM rubber hose, NBR rubber hose, Nature rubber hose. Identified by application, mainly are garden hose, air hose, oxy-acetylene welding hose, fuel/diesel hose, cooling water hose, etc.

-

Fuel/Diesel Hose

PANDA can use all kinds of rubber compounds to produce a variety of commercial and industrial rubber hose. Identified by material, mainly are EPDM rubber hose, NBR rubber hose, Nature rubber hose. Identified by application, mainly are garden hose, air hose, oxy-acetylene welding hose, fuel/diesel hose, cooling water hose, etc.

Our Product

We have many years of industry experience,

the main products are Rubber Compound, rubber products

molds and so on

Our Mission

Consistent Quality

PANDA is a quality-first company. Every batch we make for you is consistently formulated and accurately reproduced. Quality is highly controlled at our processing plants and routinely tested at the client’s facilities by PANDA experts. Whether you extrude, calender, inject, compress, or form, PANDA rubber compounds perform.

Our Goal

Technical Excellence

At PANDA, we’re chemists as much as compounders. As such, we’ll make virtually any rubber compound you need or draw from our extensive library of compound recipes. Then, we’ll fine-tune your recipe for your operations. We continue to invest in world-class, responsible, efficient technology.

Our Expertise

Comprehensive Capabilities

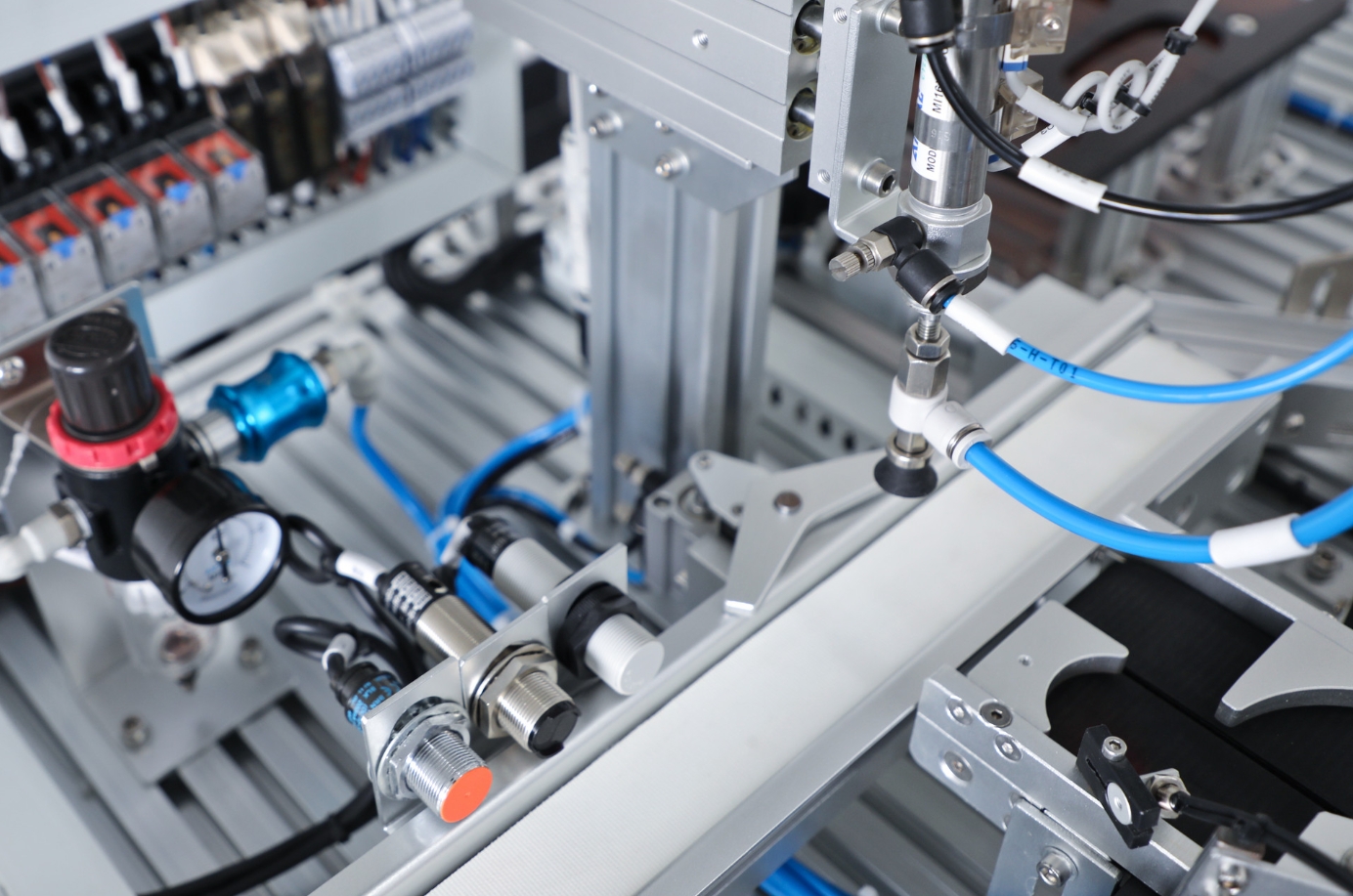

With three manufacturing facilities in China, Vietnam and Russia, we offer broad supply capability, short lead times, and on-time delivery through efficient freight lanes for delivery anywhere in these three countries and also all over the world. We can also convert compounds with our calendering, extruding, and molding expertise.

Our Promise

Transparency

We share invaluable insights like recipes, workflow progress, market trends and predictions, and formula changes with our clients and partners.

PRODUCT

CONTACT US

NEWS

-

TYRENE BUTADIENE RUBBER (SBR) COMPOUND

Styrene-butadiene rubber (SBR) describe families of synthetic rubbers derived from styrene and butadiene. These materials have good abrasion resistance and good aging stability when protected by additives. SBR is derived from two monomers, styrene, and butadiene. The mixture of these two monomers is polymerized by two processes: from solution (S-SBR) or as an emulsion (E-SBR).

넶728 2024-09-09 -

NITRILE RUBBER COMPOUND

Nitrile rubber is known for excellent resistance to many oils, especially alkane oil), abrasion, many acids, and water. Which means it has high wear resistance, good air tightness, good heat resistance, strong adhesion, good aging resistance, high elasticity, grease resistance and corrosion resistance. Also called NBR rubber, or nitrile butadiene rubber, Buna N, and Perbunan, nitrile is primarily specified where oil resistance is required.

Nitrile butadiene rubber has good elong넶682 2024-09-09 -

NATURE RUBBER COMPOUND

Natural rubber is used where toughness and durability is required, mining, tires, bushings, bearings, and molded technical goods. Talk to us about applying our formidable technical skills to your business challenges. Better performance at a better price is distinctly possible. With PANDA.Natural rubber is used where toughness and durability is required, mining, tires, bushings, bearings, and molded technical goods. Talk to us about applying our formidable technical skill

넶725 2024-09-09

WE ARE IN SOCIAL NETWORKS

© All rights reserved 2024